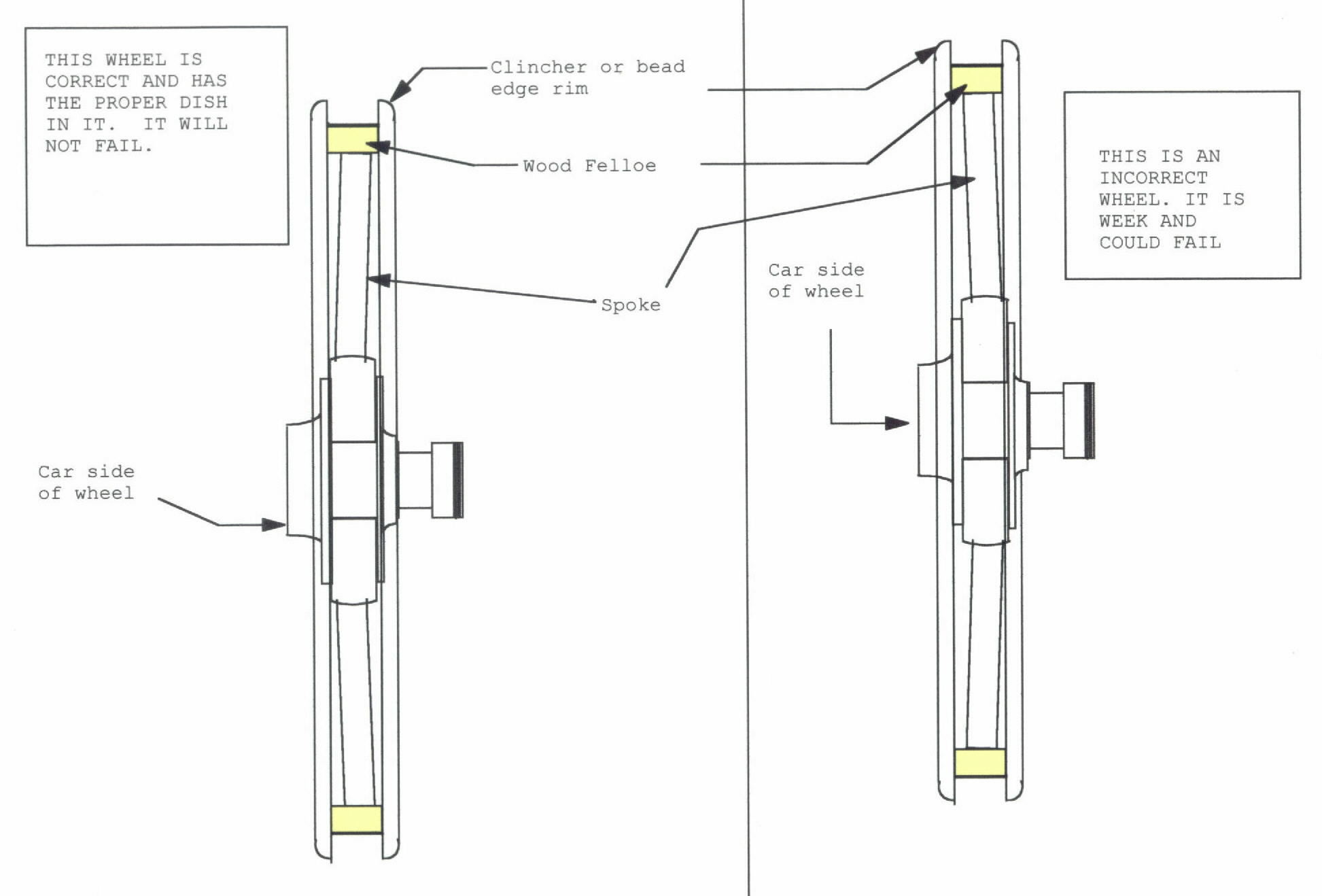

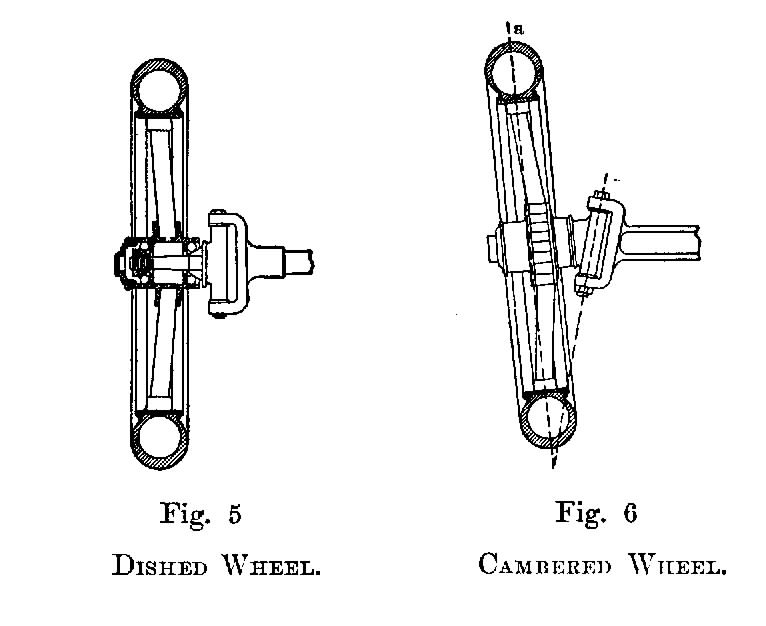

Wooden automobile wheels are generally "dished" in the manner shown in Fig. 5, the dishing consisting of a slight outward flare of all the spokes, so that they resemble a very much flattened cone, of which the wheel rim forms the base, and the hub the apex. This dishing permits the spokes to meet stresses, especially side stresses, partly by their lateral elasticity. It also renders it easy to keep the wheels tight, regardless of slight expansion and contraction in the rim and spokes, besides minimizing the breakage that inevitably comes from too rigid resistance of shocks.

The effect of "dishing" is to transform the spokes into so many springs, possessing elastic properties, and to render the wheels capable of being deformed under sidewise stress. The shocks of collision with obstacles are thus distributed through the connected parts, as could not be the case if the wheel were made in one piece or on one plane, and the consequent wear and strain are greatly reduced. The dish of the wheels is usually balanced by slightly inclining the axle spindle from its center line, thus bringing the lowest spoke to a nearly vertical position with relation to the ground.

Cambered Wheels.

In addition to the dishing, automobile wheels often are "cambered," as shown in Fig. 6, their tops being thrown slightly outward. Located outside of the tread line where the wheels rest on the ground. This camber is desirable for dished wheels, because it makes them resist side thrusts in an elastic manner, and yet permits them to stand with the weight resting solidly on the ends of their spokes.

Front wheels, dished or not, should be cambered to facilitate easy steering, How cambering helps in this respect will be seen in Fig. 6, in which it is evident that the outward rake, due to the cambering, places the point of support on the ground, in line with the axis through which the steering pivot turns. Fig. 6 shows the two dotted lines, a, through the wheel, and b, through the steering pivot, meeting at the ground.

Since a large part of the real efficiency of a dished wheel lies in its being inclined to the axis, various methods of cambering the rear wheels have been adopted, the principal method being to incline the rear axle and have the wheels run at right angles to this shaft.

The better grade of wheels are provided with at least ten spokes for the front and twelve spokes for the rear, and the spokes are set at an angle, giving a "dished" effect. This is not with a view to enhancing the appearance, but with the idea of enormoualy increasing the ability of a wheel to sustain against side strain. The amount of camber given the wheels is enough, so that the spokes are appreciably longer than the radial distance from the hub to the felly. Because of this distance and its influence, a wheel cannot be "dished" by an outside force out of the plane it is given at the time of its construction, unless the rim and felly part. The reason for this lies in the fact that all the spokes are in compression, and all share the responsibilities equally. It is not necessary, then, to have spokes of large section and great weight, whereas, on the other hand, resiliency is imparted to the wheel if the spokes are not of such great section, especially if they are whittled down in such a way as to make them rigid in the sheer plane only.

From Practical Treatise on Automobiles 1915 Edition

Home Page