Effects of the loss of moisture on wheels.

Wood is a "living" material that expands and contracts with changes in relative humidity found in our environment. Therefore the wood used in wheels must be dried to a low moisture content and maintained there while the wheel is being made. Air dried wood is not dry enough, so it must be kiln dried to force out the moisture.

Kiln drying adds to the length of time required to make new wheels as well as to the cost of manufacturing them. This drying process extends the life of the wheel by allowing the wheel to remain tight for a longer period of time than would be possible with air dried material alone.

The following pictures illustrate the effects of drying the wood.

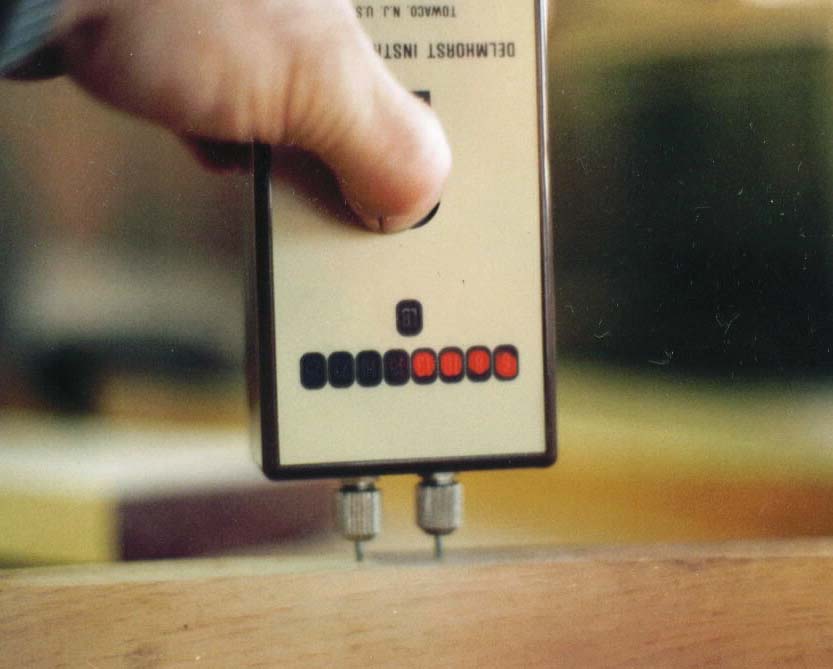

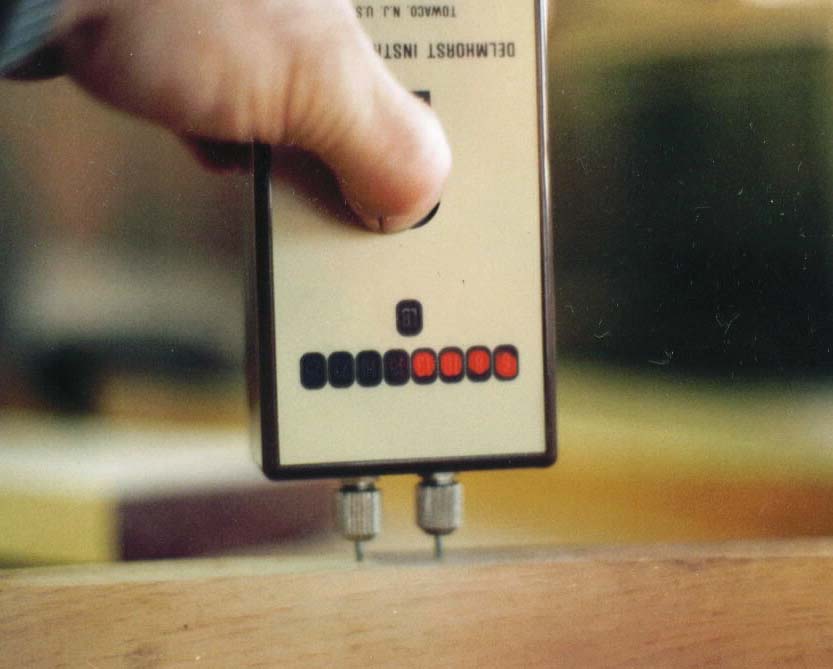

The picture below is of a piece of air dried lumber showing the moisture content of about 13%.

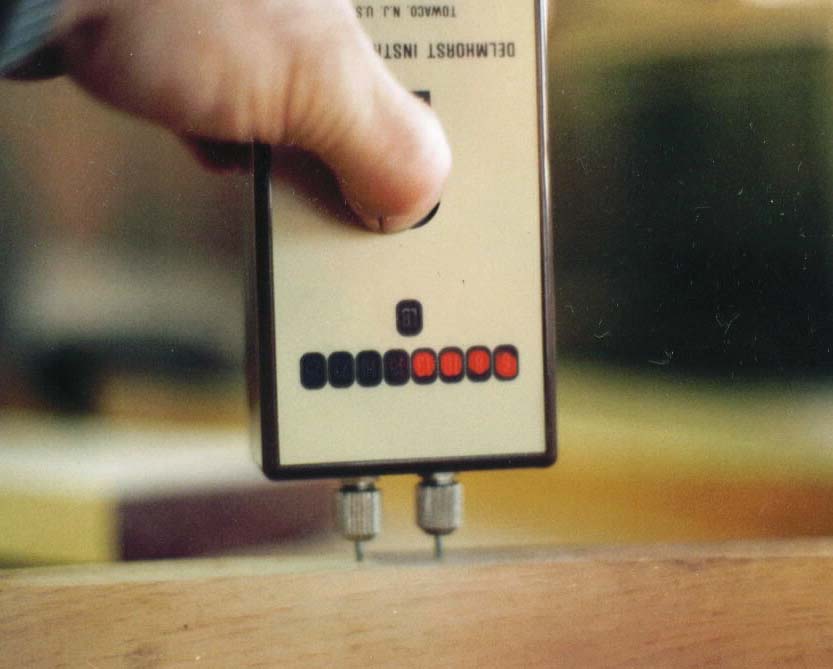

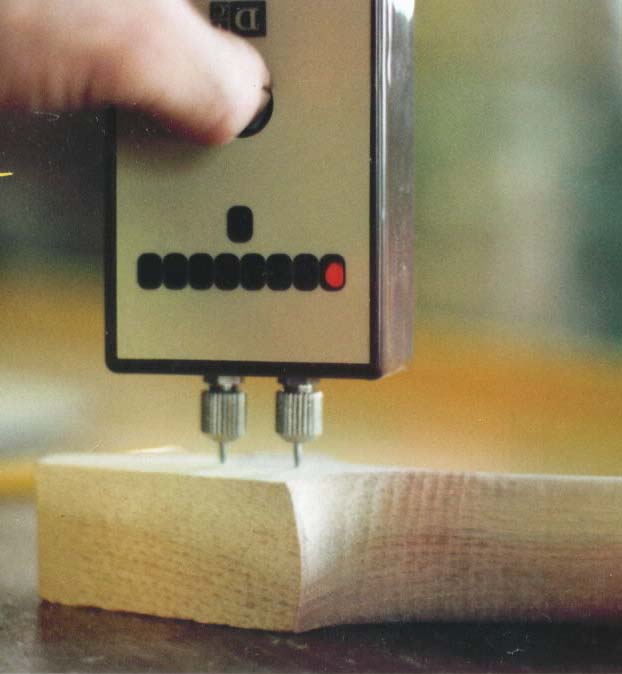

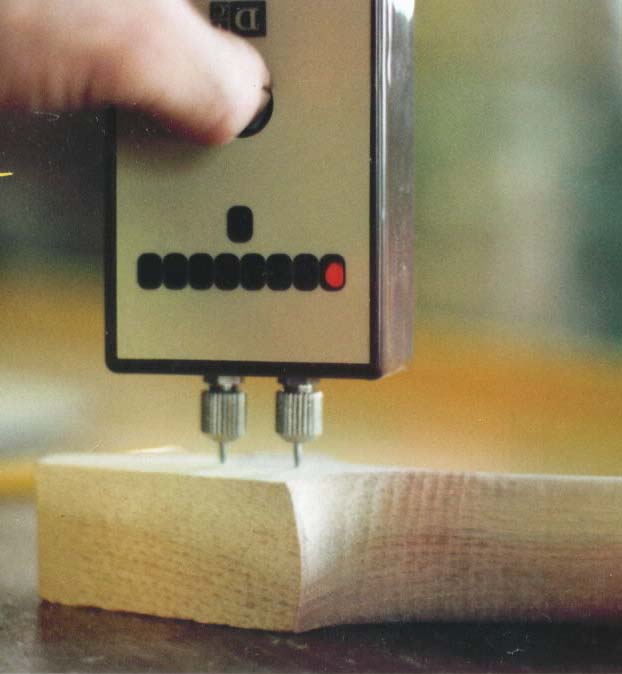

This next picture shows spoke that has been dried to 6% moisture content.

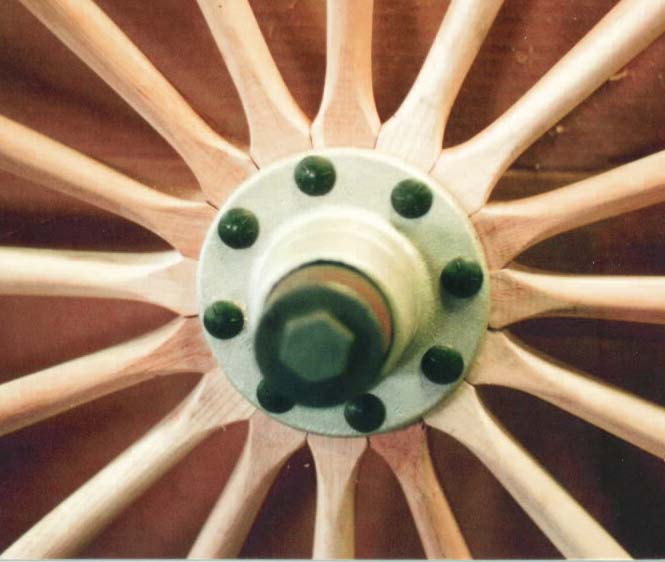

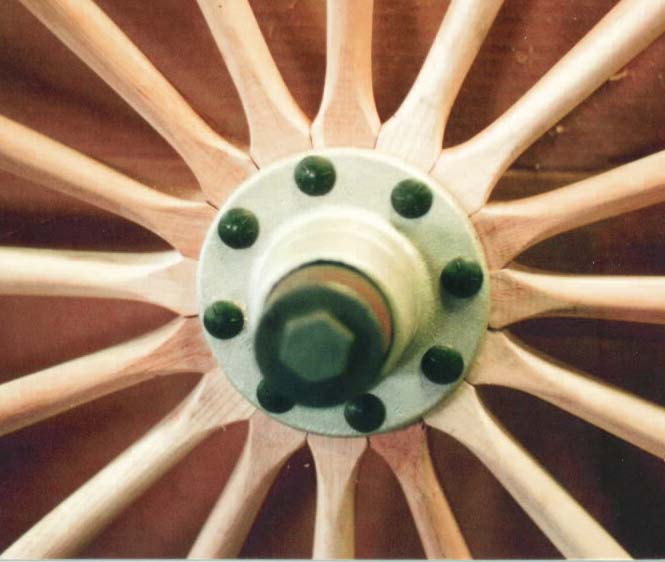

The final picture shows the effects of the loss of moisture on spokes. This wheel was built with air dried lumber with the spoke joints tight together and then placed in my drying room for a few days. You can clearly see gaps between all the spokes around the hub. This is what happens when wood shrinks from 13% to 6% moisture content. Imagine if each spoke only shrank 1/64th of an inch. This wheel, with 16 spokes, would have a total shrinkage of 1/4 inch! This wheel looks as if it shrank more than that. It is quite evident that wood for wheels must be dried prior to any assembly.

Calimer's Wheel Shop

30 East North St

Waynesboro,

PA 17268

USA

Phone-717-762-5056

Questions and CommentsHome Page